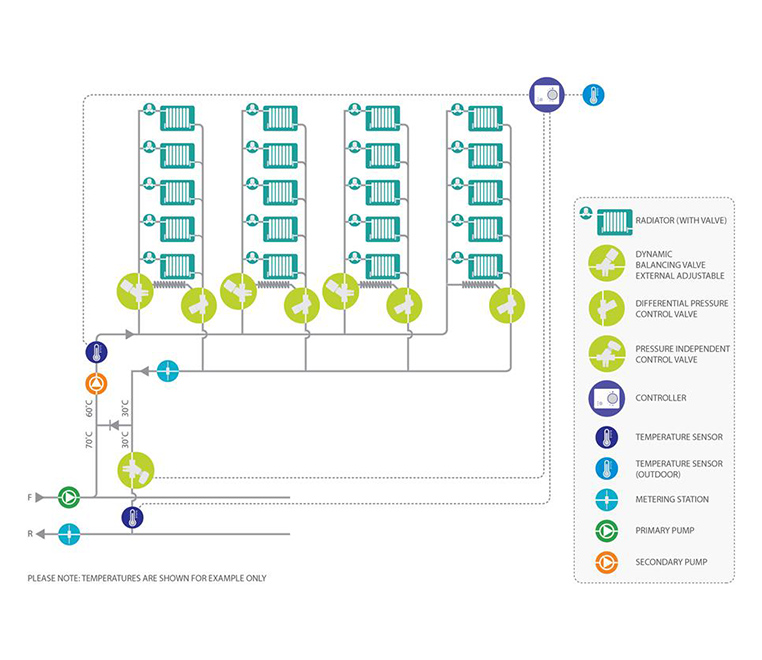

Radiator System

with DPCV and dynamic balancing

Function

The room temperature is controlled by the radiator valve on each radiator.

The balance of the system is handled by the installation of a dynamic balancing valve on each riser/branch, controlling the flow rate through this section of the system.

The dynamic balancing valve is a flow limiter that prevents overflow in the part of the system controlled by the valve.

This will ensure that the design flow is always available in all parts of the system.

A DPCV controlling the differential pressure at each riser prevents from noise in the system and allows the radiator valves to regulate and close when required.

The temperature from the primary circuit is lowered to an optimal inlet temperature at the secondary side, with a heat PICV injection circuit connected to a controller.

Benefits

- The flow rate through the dynamic balancing valve is independent of the differential pressure across it.

- The flow can be set without the use of a manometer/commissioning device.

- Only 1 dynamic balancing valve in series.

- If the system is expanded, it will not need to be rebalanced.

- No straight lengths of pipe before or after the dynamic balancing valve are required.

- Prevents noise in the system and provides good modulation to the radiator valves.

- All sections will have a defined DP available.

Considerations

- Higher cost from both DP control valve and dynamic balancing valve

- A metering station can be installed if additional flow verification is required by the witnessing authority.